Previous Page | Right click this page to print.

High Moisture Forages - Silage

Silage is a high-moisture forage; 60 to greater than 70% moisture. Silage is produced from the controlled fermentation of high-moisture forages. Silage is harvested at optimal stages of forage growth and fed as necessary. Given appropriate management, ensiled forages are a palatable feedstuff with a high nutritional value. Silage is primarily fed to beef and dairy cattle.

Figures 9.11 and 9.12 illustrate beef cattle and dairy cattle, respectively,

consuming rations containing silage.

Ensiled forages may also be fed to sheep and horses. Across species, silage

will produce favorable production results. To maximize the dry-matter

intake of silage, ensile forages at the minimum moisture levels required

for the ensiling process. Grass and legume forages and corn and sorghum

grain crops, as well as various crop surpluses and residues may be effectively

ensiled. Silage is an effective harvesting method to maximize the yield

of digestible nutrients per unit of land.

Ensiling refers to the process in which high-moisture forages are harvested

in the field, loaded into a structure, and anaerobic fermentation by microorganisms

preserves the nutrients in the forage. The primary factors influencing

the efficiency of the ensiling process are the physical and chemical properties

of the forage, establishment and maintenance of an anaerobic environment,

composition and activity of the population of microorganisms, and management

of feed-out. Given proper management, the duration of the ensiling period

is approximately two to three weeks. The ensiling process and feeding

of the silage may be divided into four phases.

Phase one is the aerobic phase and begins immediately after forage harvest.

Plant enzymes and aerobic microorganisms will convert organic materials

to carbon dioxide, water, and heat. The primary nutrients metabolized

in this phase are nonstructural carbohydrates and proteins. Extended duration

of phase one may result in excessive nutrient loss and excessive heating

of the forage. Phase one decreases the nutritional value of the forage,

therefore establishment and maintenance of anaerobic conditions in the

ensiling structure is essential to maximize nutritional value of the forage.

Phase one is completed with the establishment of anaerobic conditions.

Given proper management, phase one will be completed in less than six

hours.

Phase two is the initial anaerobic fermentation of the ensiled forage.

During phase two, acetic acid producing microorganisms predominate. Acetic

acid producing bacteria ferment nonstructural carbohydrates to acetic

acid. Acetic acid functions as an energy source for the ruminant and also

to reduce the pH to approximately 5.0. Reduction of the pH will inhibit

the acetic acid producing microorganisms and set up phase three. Under

ideal conditions, the duration of phase two is one to three days.

Phase three is the characterized by the growth of the lactic acid producing

microorganisms. During phase three, lactic acid producing bacteria ferment

nonstructural carbohydrates to lactic acid. Lactic acid is the most desirable

of the acids. Lactic acid is a strong acid. In addition, lactic acid can

be used as an energy source for ruminants. Lactic acid is also palatable

for ruminants. Phase three is completed when the production of lactic

acid has decreased the pH of the forage to 4.0-4.5, inhibiting the growth

of microorganisms, and therefore effectively preserving the nutrients

in the forage. The pH and the composition of acids in silage are two indicators

of efficiency of fermentation and quality of silage. The optimal pH for

grass silage and corn silage is approximately 4.5 and 4.0, respectively.

In a high-quality silage, lactic acid is the predominant acid in a high-quality

silage; 4-8% of the silage dry-matter. An excessive level of butyric acid

is an indicator of a lower quality silage.

Phase four is the feed-out phase; the period of time in which silage is

unloaded from the ensiling structure and fed. During the feed-out phase,

the ensiled forage is exposed to oxygen and oxygen initiates secondary

aerobic degradation of the forage by microorganisms and will also facilitate

the growth of yeast and fungi. During the feed-out phase it is essential

to minimize the duration of time from exposure to oxygen to animal consumption,

to minimize secondary degradation and maximize nutritional value of the

ensiled forage.

Initially, the forages are harvested or cut in the field.

Figure 9.13 illustrates corn silage being cut, chopped, and transferred

to a forage wagon in the field.

As with other harvested forages, harvesting at the appropriate stage of

maturity is essential to maximize yield of digestible nutrients per unit

of land. Table 7-20 on page 147 of the text describes the harvest maturity

for optimum ensiling for the various forages.

In addition, the decision regarding harvest accounts for moisture and

nonstructural carbohydrate content of the forage. Appropriate moisture

content improves the efficiency of microbial fermentation, aids in the

establishment of anaerobic conditions, and minimizes seepage. Optimal

moisture content at ensiling varies by type of silo and forage species.

Table 7-21 on page 148 describes methods to estimate the moisture content

of forage. Table 7-20 on page 147 describes an acceptable range of moisture

at ensiling for the various forages.

Figure 9.14 describes the associated losses at various moisture levels

with the various ensiling structures.

Dependent on moisture level, silage is classified as direct-cut silage,

70% or greater moisture, wilted silage, 60-70%, or low-moisture silage;

40-60% moisture. In general, corn and other grain crops are direct-cut

silage; harvested and immediately ensiled. In contrast, grasses and legumes

are generally harvested, allowed to wilt in the field to the predetermined

moisture content, and then ensiled.

Figure 9.15 illustrates wilted forage being collected, chopped, and transferred

to a wagon in the field.

The nonstructural carbohydrate content of the forage influences the efficiency

of the ensiling process. Nonstructural carbohydrates are the primary substrate

for acid production by the microorganisms during the ensiling process.

Optimal forage maturity at harvest will promote adequate levels of nonstructural

carbohydrates.

Next, the forage is chopped, transported to the ensiling structure, and

ensiled. Chopping promotes the exclusion of oxygen from the forage in

the ensiling structure and therefore decreases the time required for establishment

of an anaerobic environment. In general, the optimal length of chop is

¼ to ½". Optimal length of chop is determined by the

type of forage, ensiling structure, and the rate of silage inclusion in

the animal ration. Tables 7-20 on page 147 describes the recommended length

of cut or chop for the various forages. Effective loading and packing

of the ensiling structure is essential to establish and maintain anaerobic

conditions and therefore set up the entire ensiling process. Loading will

also influence unloading of the silage. The ensiling structure should

be loaded rapidly, continuously, and consistently. The forage should also

be packed consistently and sealed rapidly. The specific method varies

with ensiling structure.

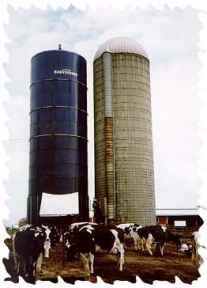

Four common ensiling structures are vertical, conventional silos (also

known as tower silos), vertical, oxygen-limiting silos, horizontal, bunker

silos, and bag silos. Vertical oxygen-limiting silos are used to store

high-moisture grains and low-moisture forages.

Figure 9.16 illustrates a vertical, conventional silo (on the right) and

a vertical, oxygen-limiting silo (on the left).

Figure 9.17 illustrates a horizontal, bunker silo.

Figure 9.18 illustrates silage being bagged.

Regardless of the specific type of ensiling structure, the ensiling structure

must provide for establishment and maintenance of an anaerobic environment

and efficient loading, packing, and unloading of the forage. Proper sizing

of the ensiling structure is essential; dimensions of the silo are influenced

by factors such as loading, packing, and unloading of the silage, quantity

of forage fed per day, and duration of time the forage will be fed.

In general, vertical silos minimize feed losses and loading and unloading

is relatively efficient. The initial capital investment for the facility

and equipment is high. Horizontal silos require a relatively low capital

investment in facilities and equipment, loading and unloading is relatively

labor-intensive, and have the potential for high feed losses. Bag silos

are bags made of heavy plastic. Capital investment is relatively low,

feed losses are minimal, and loading and unloading is relatively labor-intensive.

To maximize the yield of digestible nutrients, it is important to minimize

losses associated with silage production. The average losses associated

with silage production are 15-25% of the total dry-matter of the forage

in the field. As a result of the moisture content of the forage, generally,

losses associated with harvesting and handling are minimal. Primary losses

associated with silage production are associated with the fermentation

stages of the ensiling process, storage of the forage, and the feed-out

phase. Table 7-22 on page 149 provides a summary of harvesting methods

for alfalfa including associated losses.

Additives may be added to the ensiled forage to improve the ensiling process

and the nutritional value of the ensiled forage. Silage additives are

not required to produce a high-quality ensiled forage. Silage additives

are not a substitute for proper silage management. In general, additives

may be classified as nutrients, chemical preservatives, or biological

agents.

NPN and other protein sources may be added to feeds low in crude protein

and high in energy to increase the crude protein content of the ensiled

forage. Fermentable carbohydrate sources such as grains and molasses may

be added to feeds low in energy and high in crude protein to improve the

efficiency of the ensiling process. Preservatives are chemical compounds

such as organic acids that reduce the degradation of crude protein and

carbohydrates, especially in direct-cut silages. In addition, various

chemicals such acids are added to inhibit select microorganisms and to

maintain the nutritional value of the forage. Bacterial cultures containing

lactic acid producing microorganisms are added to the ensiled forage to

promote establishment of and fermentation by lactic acid producing microorganisms.

Microbial enzymes may also be added to ensiled forages to increase the

quantity of nutrients available for fermentation of the forage.

The nutritional value of silage may be evaluated via sensory and analytical

methods. Sensory evaluation includes use of visual, tactile, and olfactory

senses. High-quality silage has a bright, crisp color, a firm texture,

has a clean, acidic odor, and is absent from antinutritional factors and

contaminants. And in addition to standard forage analyses, the pH, the

composition of acids and the nitrogen component may be also be analyzed

to estimate nutritional value of the forage.

In the U.S., corn is the most popular ensiled forage.

Figure 9.19 illustrates a field of corn silage.

Figure 9.20 illustrates corn silage being harvested.

Corn silage has favorable characteristics associated with crop production,

nutritional value, and feeding value. As a crop, corn silage produces

a high yield of digestible nutrients per unit of land. Corn silage is

a source of structural carbohydrates and nonstructural carbohydrates (e.g.

energy) for ruminants. In general, corn silage is high to moderate in

digestible energy and low to moderate in crude protein. On a dry-matter

basis, the TDN and crude protein concentrations of corn silage are 65-75%

and 8-9%, respectively. As energy is a primary component of corn silage,

forage producers should manage the forage to maximize the energy yield

per unit of land. The average NDF and ADF content is 51% and 28%, respectively.

Corn silage is a very palatable feedstuff. To maximize the nutritional

value of corn silage requires addition of protein, mineral, vitamin, and

potentially, energy supplements to the ration.

Management factors influencing the yield of digestible nutrients of corn

silage include hybrid selection, fertilization, maturity at harvest, and

harvest, storage, and feeding management. Stage of maturity at harvest

influences yield and digestibility of nutrients as well as ensiling characteristics.

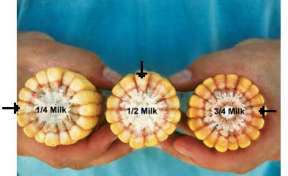

Optimum stage of maturity at harvest is identified by the location of

the milk line. The milk line is the line in the kernel separating the

liquid and solid portions of the kernel.

Figure 9.21 illustrates the various milk lines.

Figure 7.16 on page 155 of the text describes the kernel milk line (e.g.

maturity) and expected dry-matter yields. As the corn plant matures, the

milk line moves from the outside to the inside of the kernel. Table 7-33

describes the plant composition and energy yields of whole plant corn

silage harvested at three different maturities. Optimal stage of maturity

to harvest corn to maximize energy value of the silage, optimize moisture

content for ensiling, and maximize animal consumption, is when the milk

line is one-half to two-thirds down the kernel. At this stage of maturity,

the moisture level of the plant will be from 65-70%. Table 7-20 describes

the optimal chop size for corn silage. To improve the nutritional value

of corn silage, corn silage may also be processed. Corn processors disrupt

the physical structures and reduce the physical size of the particles

of the plant, increasing the nutritional value of the corn silage.

Additional ensiled forages include sorghum, grasses, legumes, small grains,

and crop residues and surpluses. While the nutritional value and various

specifics regarding silage production will differ, the basic principles

of silage production also apply to these forages.

Ensiling of forage may also be a means to manage specific forage issues.

For forages with high levels of nitrate, prussic acid, and various other

compounds ensiling will reduce the amounts of these compounds. In addition,

for legumes, ensiling will reduce the opportunity for bloat.

Previous Page | Right click this page to print.