|

|

|

| Welcome | Getting Started | Resources | Site Map |

Week 4

Roughages |

Instructions for listening to audio clips

- Download the QuickTime Player to listen to the audio files.

- Read the QuickTime Instructions for installation help.

- Download the RealPlayer to listen to the audio files

- Instructions are on the RealPlayer download page

High moisture forages Silage

Follow along with the audio...

- High-moisture forage

- 60% to greater than 70% moisture

- Controlled fermentation of high-moisture forages

- Harvested at stages of forage growth and fed as necessary

- Given appropriate management

- Palatable

- High nutritional value

- Primarily fed to beef and dairy cattle

- Figures 9.11 and 9.12 Consuming rations containing silage

- Fed to sheep and horses

- Favorable production results

- Maximize DMI, ensile at minimum moisture required for ensiling

- Ensiled

- Grass and legume forages

- Corn and sorghum grain crops

- Various crop surpluses and residues

- Effective method to maximize yield of digestible nutrients per unit of land

- Ensiling

- Process

- High-moisture forages harvested

- Loaded into structure

- Anaerobic fermentation preserves nutrients

- Factors

- Physical and chemical properties of forage

- Establishment and maintenance of anaerobic environment

- Composition and activity of population of microorganisms

- Approximately 2-3 weeks

- Phase one

- Aerobic

- Immediately after harvest

- Plant enzymes and aerobic microorganisms

- Convert organic materials to carbon dioxide, water, and heat

- Nonstructural CHO and proteins

- Extended duration

- Excessive nutrient loss and heating

- Completed with establishment of anaerobic conditions

- Less than six hours

- Phase two

- Initial anaerobic fermentation

- Acetic acid producing microorganisms

- Nonstructural CHO to acetic acid

- Acetic acid

- Energy source

- Reduce pH to app. 5.0

- One to three days

- Phase three

- Lactic acid producing microorganisms

- Nonstructural CHO to lactic acid

- Lactic acid

- Most desirable acid

- Strong acid

- Energy source

- Palatable

- Completed when pH is 4.0-4.5

- Inhibiting microbial growth

- Preserving nutrients in forage

- Indicators

- pH

- Grass: 4.5

- Corn silage: 4.0

- Composition of acids

- Lactic acid predominate

- 4-8% of DM

- Phase four

- Feed-out

- Period in which unloaded from structure and fed

- Exposed to oxygen

- Oxygen initiates secondary aerobic degradation and yeast and fungi growth

- Minimize duration of time from exposure to oxygen to animal consumption

- Harvesting

- Figure 9.13 Corn silage being cut, chopped, and transferred to forage wagon in field

- Stage of maturity

- To maximize yield of digestible nutrients per unit of land

- Table 7-20 on page 147 of text Harvest maturity for various forages

- Moisture content

- Efficiency of microbial fermentation, establishment of anaerobic conditions, and minimizes seepage

- Varies by silo and forage

- Table 7-21 on page 148 Methods to estimate moisture content of forage

- Table 7-20 on page 147 Acceptable range of moisture at ensiling for various forages

- Figure 9.14 Associated losses at various moisture levels with various ensiling structures

- Classifications

- Direct-cut; 70% or greater moisture

- Corn and other grain crops

- Wilted; 60-70% moisture

- Grasses and legumes

- Figure 9.15 Wilted forage collected, chopped, and transferred to wagon in field

- Low-moisture; 40-60% moisture

- Grasses and legumes

- Nonstructural CHO content

- Efficiency of ensiling process

- Primary substrate for acid production

- Optimal maturity promotes adequate levels

- Chopping

- Promotes establishment of anaerobic conditions

- In general, optimal is 1/4 to 1/2

- Type of forage, ensiling structure, and rate of inclusion in ration

- Table 7-20 on page 147 Recommended length of cut or chop for various forages

- Loading and packing

- Loading

- Establish and maintain anaerobic conditions

- Unloading

- Rapidly, continuously, consistently

- Packing

- Establish and maintain anaerobic conditions

- Consistently and sealed rapidly

- Method dependent on ensiling structure

- Ensiling structure

- Vertical, conventional silos (tower silos)

- Figure 9.16 - Vertical, conventional silo (right)

- Vertical, oxygen-limiting silos

- Figure 9.16 Vertical, oxygen-limiting silo (left)

- Oxygen-limiting store high-moisture grains and low-moisture forages

- Horizontal, bunker silos

- Figure 9.17 Horizontal, bunker silo

- Bag silos

- Figure 9.18 - Silage being bagged

- Requirements

- Establishment and maintenance of anaerobic environment

- Efficient loading, packing, and unloading

- Sizing

- Factors

- Loading, packing, and unloading of silage

- Quantity of forage fed per day

- Duration of time forage fed

- Vertical

- Minimize feed losses

- Loading and unloading efficient

- High investment in facility and equipment

- Horizontal

- Low capital investment in facilities and equipment

- Loading and unloading labor-intensive

- Potential for high feed losses

- Bags

- Low capital investment

- Minimal feed losses

- Loading and unloading labor-intensive

- Losses

- Minimize to maximize yield of digestible nutrients

- Average losses are 15-25% of DM

- Associated with harvesting and handling minimal

- Primary losses associated with fermentation, storage, and feed-out

- Table 7-22 on page 149 Summary of harvesting methods for alfalfa with associated losses

- Additives

- Improve the ensiling process and nutritional value of ensiled forage

- Not required

- Not substitute for management

- Classified

- Nutrients

- NPN and other protein sources

- Feeds low in CP and high in energy

- Increase CP

- Fermentable CHO sources

- Grains and molasses

- Feeds low in energy and high in CP

- Efficiency of ensiling process

- Chemical preservatives

- Organic acids

- Reduce degradation of CP and CHO

- Especially, direct-cut

- Inhibit select microorganism

- Biological agents

- Lactic acid producing microorganisms

- Establishment of and fermentation by lactic acid producers

- Microbial enzymes

- Increase quantity of nutrients available for fermentation

- Evaluation of nutritional value

- Sensory

- Visual, tactile, and olfactory senses

- Bright, crisp color, firm texture, clean acidic odor, and absent from antinutritional factors and contaminants

- Analytical

- Standard forage analyses

- pH

- Composition of acids

- Nitrogen component

- Corn silage

- In U.S., most popular ensiled forage

- Figure 9.19 Field of corn silage

- Figure 9.20 Corn silage being harvested

- Favorable characteristics associated with crop production, nutritional value, and feeding value

- Crop production

- High yield of digestible nutrients per unit of land

- Nutritional value

- Structural CHO and nonstructural CHO (e.g. energy)

- High to moderate in DE

- TDN

- 65-75% of DM

- Low to moderate in CP

- 8-9%

- Average NDF

- 51%

- Average ADF

- 28%

- Feeding value

- Palatable

- Supplement with protein, mineral, vitamin, and potentially, energy to maximize nutritional value

- Factors

- Hybrid selection

- Fertilization

- Maturity at harvest

- Yield and digestibility of nutrients and ensiling characteristics

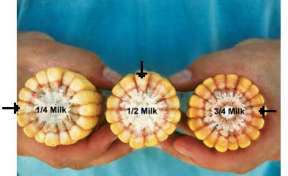

- Identified by location of milk line

- Milk line

- Line in kernel separating liquid and solid portions of kernel

- Figure 9.21 Various milk lines

- Figure 7.16 on page 155 of text Kernel milk line (e.g. maturity) and expected DM yields

- As plant matures, outside to inside

- Table 7-33 Plant composition and energy yields of whole plant corn harvested at three different maturities

- Optimal stage to maximize energy value of silage, moisture content for ensiling, and maximize animal consumption is one-half to two-thirds down kernel

- Moisture level 65-70%

- Harvest, storage, and feeding management

- Chop size

- Table 7-20 on page 147 Optimal chop size for corn silage

- Processing

- Improve nutritional value

- Disrupt physical structures and reduce physical size of particles of plant

- Additional ensiled forages

- Sorghum, grasses, legumes, small grains, and crop residues and surpluses

- Nutritional value and various silage production specifics will differ, basic principles of silage production also apply

- Ensiling also means to manage specific forage issues

- Ensiling will reduce nitrate, prussic acid, and various other

compounds, and reduce opportunity for bloat

- Ensiling will reduce nitrate, prussic acid, and various other

compounds, and reduce opportunity for bloat

| |

| Welcome | Getting Started | Resources | SiteMap |